Success Story: Maastricht University Circular Plastics Lab

Keeping Plastics in the Loop

Making it happen—that's the motto of Maastricht University's Circular Plastics Lab. And for good reason. Here, students and scientists work to identify, analyze, and conquer the challenges plastics face on the road to a fully sustainable future. Their aim: to drive innovation in the circular economy… and make it happen. Kubota Brabender Technologie provides advanced feeding technology and industrial expertise for this cutting-edge research.

Researching to Improve Lives

"Our goal is simple: We want to improve lives through chemistry research," says Carlo Taglienti, Circular Plastics Lab Manager. "To realize this goal, we have pioneered a brand-new field of engineering sciences, and are conducting fundamental and applied research in polymers and plastics processing in close cooperation with the industry."

Young, interdisciplinary, and socially engaged, Maastricht University (UM) has established an international reputation of groundbreaking research and excellent education. It's no surprise that the new discipline of Circular Engineering was born in this particular place of learning. The university places particular emphasis on connecting science with regional, European, and global challenges; students from all over the world come together to work towards a sustainable economy and a healthy world for everyone. An ideology that aligns perfectly with Kubota Brabender Technologie's convictions.

Circular Plastics for the Future

The Circular Plastics Chair is part of Maastricht University’s Faculty of Science and Engineering. With close cooperations across academia and the industry, the Circular Plastics Lab's research is funded by industry partners as well as public grants. Researchers tackle core challenges in plastic recycling—from material quality to real-time process control. The lab also plays a key role in the Bachelor’s program in Circular Engineering, supporting students' interdisciplinary training in sustainable materials and engineering solutions for a green future.

The Circular Plastics Lab is located in Brightlands Chemelot Campus – a joint initiative of Maastricht University, the Province of Limburg, and dsm-firmenich. The campus is one of the largest research and business parks in Europe and a leading location in chemistry and materials. Here, entrepreneurs, researchers, and students come together to make a difference by addressing global sustainability, climate, and health challenges.

Innovation in Plastics

"Plastics are omnipresent in today's economy, which makes it extremely important they become sustainable," Taglienti says. "Our research looks at the entire plastics value chain, focussing on materials. By enhancing plastics and recyclate quality, we supply the industry with the means to move closer to a fully circular value chain." This is relevant for most industries, and poses a particularly pressing issue for the packaging, automotive, electrical, and electronics sectors.

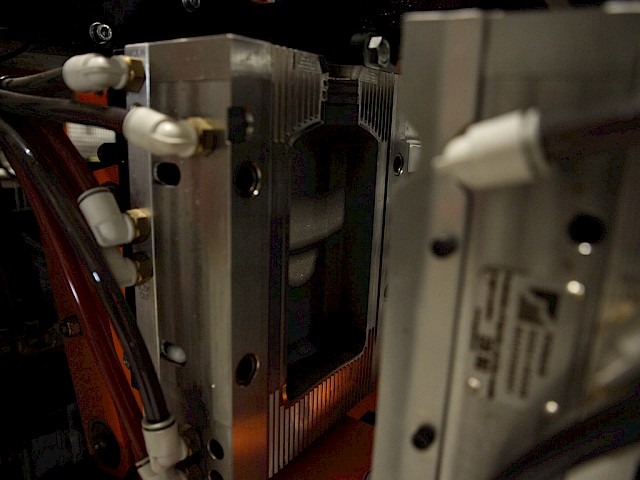

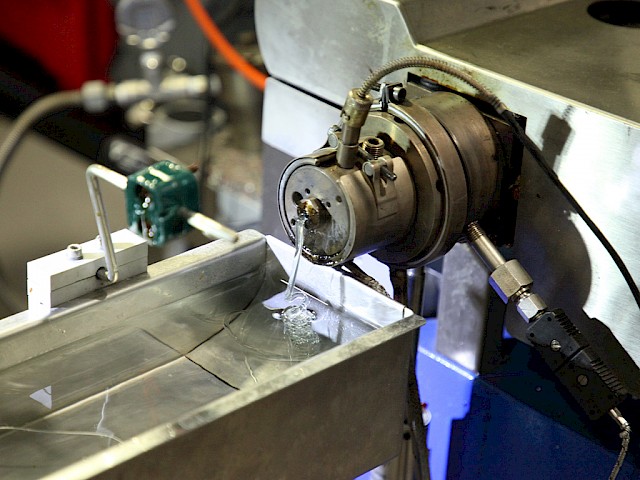

In the Circular Plastics Lab, researchers model production processes using top-of-the-line industrial equipment. Kubota Brabender Technologie's feeding solutions play an important role in all of these processes. Compounding—creating plastic materials by blending molten polymers and additives—relies on the precise supply of ingredients by high-quality feeders. Blown film and cast film extrusion, production methods that produce flat plastic films for products like plastic bags and packaging films, are equally dependent on precise feeding systems. So, too, are hot press forming, injection molding, and blow molding, which is used to produce bottles and other hollow plastic products.

The Ideal Feeding Solutions

"Kubota Brabender Technologie's industrial equipment is invaluable to us," Taglienti reports. "It allows us to train students and researchers in a hands-on environment, and supports the development of new applications and products." And it's not all about technology. The expert in industrial feeding solutions also supports the lab's research by providing valuable insights into market needs and product requirements. The result: more relevant, application-oriented research.

For Taglienti and his fellow researchers, partnering with Kubota Brabender Technologie was an easy choice. The precision Kubota Brabender Technologie's solutions ensure when feeding small quantities was a deciding factor; the Circular Plastics Lab works with far smaller batches than most industrial applications, and feeders must be able to reliably measure out product in the gram range. The devices' robustness was also a powerful argument, as was the competent, hands-on help Kubota Brabender Technologie provides should problems arise. Taglienti also emphasizes the role sincerity and openness played in the team's decision: "From the beginning, we appreciated Kubota Brabender Technologie's open and honest communication. It laid a solid foundation for our cooperation."

Building a Better Future: The European Green Deal

The European Green Deal aims to transform Europe into a sustainable economy and achieve climate neutrality by 2050. To realize this important goal, the EU has launched a number of initiatives to reduce greenhouse gas emissions, invest in green technologies, and promote sustainable industry and agriculture.

Our world is facing serious environmental challenges, from waste and pollution to resource depletion. To meet these challenges, we must rethink our methods of production, consumption, and waste management. The shift from a linear to a circular economy is a critical cornerstone of the green transition, and European governments and corporations are increasingly embracing the principle of circularity. At the same time, consumers grow more and more aware of their everyday actions' impact on the environment and strive to change linear habits.

Research that Makes Progress Happen

In UM's Circular Plastics Lab, Kubota Brabender Technologie's feeders support a large number of EU- and industry-funded research projects. The project Circular FoodPack—to name one example—focusses on recycling plastic food packaging and investigates waste sorting, plastic pretreatments like de-inking, and the combination of mechanical and dissolution-based recycling methods. INCREACE aims to increase the recycled content of products containing plastic, starting from five business cases to identify and clear hurdles. MoQuP-R, meanwhile, is a real-time quality monitoring system in development, aiming to ensure quality along the mechanical recycling chain by controlling chemical composition and melt properties.

And these are merely three of many promising projects. Other research subjects include analyzing the degradation, processing, and recycling of PP/FR plastics with a view to developing new materials and increasing recyclate quality, looking into advanced mechanical recycling technologies for food-grade polyolefins, enhancing recycling quality for flexible plastics, and improving the sustainability of PET recycling by tackling PLA contamination.

Partners for a Sustainable Tomorrow

Not incidentally: The feeding expert and the UM researchers have much in common. They share the same vision on innovation, sustainability, and social responsibility. Both are committed to a sustainable future and circular economy, which gives their cooperation an ideal basis for further growth. "We intend to deepen our collaboration by jointly investing in new technologies and equipment," Taglienti reports. "We are convinced that in the long term, our partnership will contribute significantly to advancing Europe's circular plastics industry."

Towards a Circular Economy

Take, make, use, dispose: In the traditional, linear economy, raw materials are extracted, used to manufacture products, and discarded at the end of the products' life. They end up in landfills, incinerators, or as environmental pollutants. This one-way system depletes valuable natural resources while generating vast amounts of waste and pollution.

On the other hand, materials in a circular economy never become waste. Products are reused, refurbished, and completely recycled, circulating through life cycles with nothing being discarded. Valuable raw materials stay available to the economy, whether as a component or through recycling and reuse. This eliminates waste and pollution and counters the problem of finite resources and supply shortages.

In short: The circular economy's closed-loop system conserves natural resources, stabilizes supply chains, reduces pollution, counters climate change, and protects and restores biodiversity and public health.

The Issue with Linear Plastics

Today, according to the EU, almost 32 million tons of plastic waste are generated every year in Europe alone. The OECD estimates that as of 2024, a mere 9% of the world’s plastic was being recycled. Plastics hold enormous significance for our economy, and are only growing more important—and because traditional plastics are not biodegradable, plastic pollution, plastic marine litter and microplastics are a pressing problem.

Completing the Circle

Innovations in key technologies like material science, waste management, and recycling play an important role in achieving a circular economy. So does collaboration across sectors, building the required infrastructure—and a new way of thinking on the part of consumers, product designers, and manufacturers.

Kubota Brabender Technologie's systems are crucial components of resource-efficient production and recycling, allowing the recovery of raw materials and preventing waste. As part of the global community and many local communities around the world, the feeding expert is committed to being part of the circular solution.