New equipment generation 2.0

If it’s modular you want, you got it!

Increasingly smaller batches, faster product changeovers and high frequency: nowadays feeders have to meet a wide range of requirements. The objective is to reduce equipment and system downtimes to a minimum. That is why feeders and other equipment have to be fast and easy to clean and have low susceptibility to malfunctions. Our product developers have factored these requirements into the new equipment generation 2.0 by creating a coherent modular concept that makes our equipment very easy to clean and access. The new modular equipment design provides users with significant benefits in terms of flexibility, cleanability, seal tightness and time efficiency throughout the entire production process.

Overview of innovations

Furthermore, all mating dimensions have been standardized following the reengineering process. On the new equipment generation 2.0, the gearing unit is now positioned directly above the load cell, while a four-lip PTFE seal ensures improved sealing. Feeders are available in a choice of three motor versions. A total of five different load cells, three digital and two analog, are also available. As far as closures are concerned, a permanently installed clamping lug system has now replaced the nut/bolt connections previously used. The downspout has been standardized on both feeders and is now particularly ideal for low feed rate applications. Downsized stainless steel bushes enable screws to meet Hygienic Design requirements and make them suitable for use in the food industry or pharmaceutical manufacturing.

Brief chronology

2019: The DDSR20 2.0 twin-screw feeder and the DSR28 2.0 single-screw feeder are the first new modular equipment generation 2.0 feeders to be unveiled.

2021: These are followed by two other, larger feeders from both product lines – the DDSR40 2.0 and the DSR67 2.0.

2022: The next largest models, the DDSR60 2.0 and DSR103 2.0, will be launched by the end of the year.

Our modular equipment generation 2.0 has enabled us to start providing customized, purpose-specific feeders that are even more efficient than before.Jürgen Knez, Head of Mechanical Systems Development at Kubota Brabender Technologie

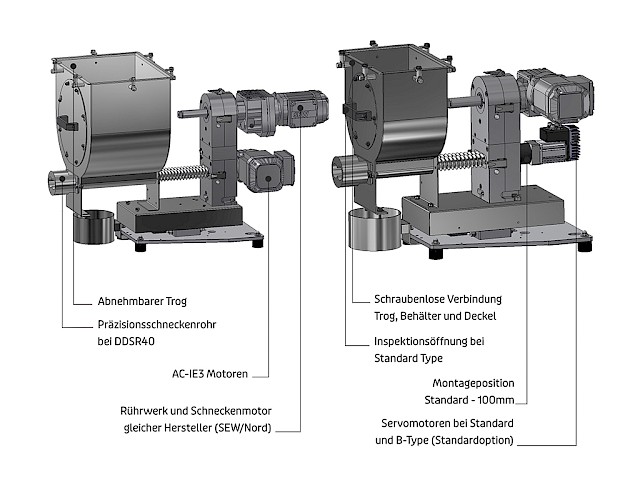

Perfectly matched modules on the DDSR40 and DSR67

Two more feeders have now been relaunched as well:

- firstly, the DDSR40 2.0 twin-screw feeder with self-cleaning twin concave screws. A feeder for handling poorly flowing, sticky bulk materials that tend towards solidification and bridging when at rest.

- secondly, the DSR67 2.0 single-screw feeder. A feeder that is predominantly equipped with a single spiral screw for handling bulk materials with limited to poor flow properties.

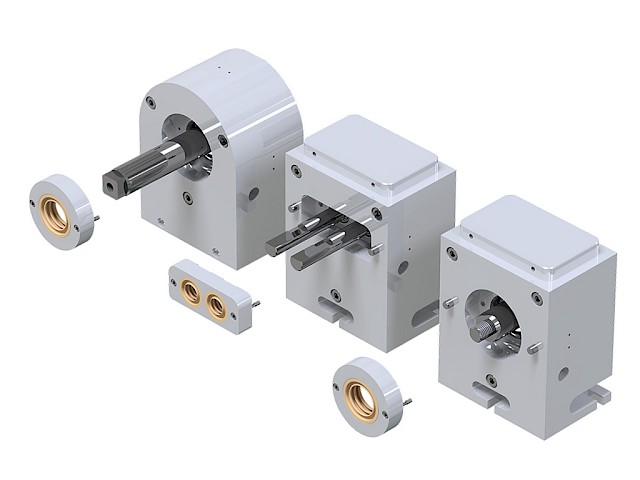

Clean and steady: the modular gearing block

Jürgen Knez, Head of Mechanical Systems Development at Kubota Brabender Technologie, explains: “The reengineering process for both these feeders focused on modular design. All modules are perfectly matched. This enables us to configure four feeder combinations using very few stock components. These are both the DDSR40 2.0 and DSR67 2.0 standard versions as well as the associated B-Type versions featuring larger troughs and hopper volumes.”

All components are aligned with the snug-fitting gearing unit, to which the motors are also attached. Knez explains: “When B-Type feeders, which have greater volume capacity and require more space, are operated, the gearing block is shifted 100 millimeters in order to upsize the feeder. The corresponding holes have been pre-drilled into the weighing platter – another modularity feature that enables retrospective switching between standard and B-Type versions post-purchase.”

This modular design means the gearing units of both feeders are quickly and easily interchangeable. They can be stripped down in just a few moves. This flexibility enables the customer to switch from large to small feeders as well as from single- to twin-screw versions and back.Jürgen Knez, Head of Mechanical Systems Development at Kubota Brabender Technologie

A direct drive mechanism with clean drivebelt technology, specially made for Kubota Brabender Technologie, has been added to the gearing block of the DDSR40 2.0 twin-screw feeder. In contrast to the gear drive previously used, this new technology operates entirely without lubricating grease. The gearing operates more quietly, weighs less and can be combined with conventional motor technology as well as with smart servo motors. This motor combination is also available for the DSR67 2.0.

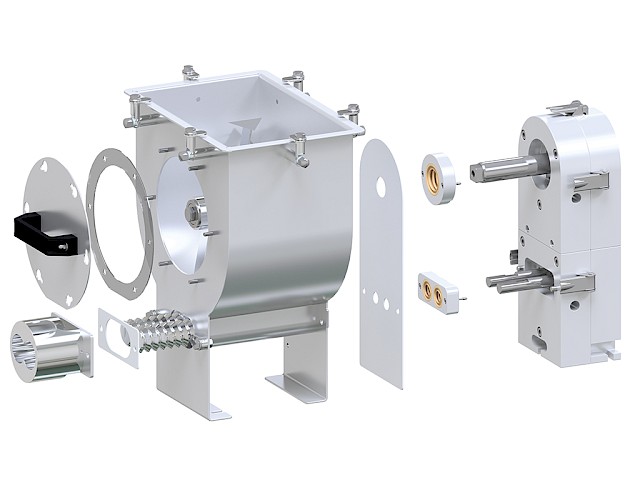

Removable trough, user-friendly quick-release closures

As part of the new modular concept, the screw trough is located right at the front of the weighing platter. “This means that the screw trough can now be conveniently removed from the front of the feeder for the first time, as on the smaller DSR28 2.0 and DDSR20 2.0 versions. Feeder accessibility as a whole has therefore been enhanced significantly and users benefit in particular from the fact that components, which come into contact with products, are quick and easy to clean,” says Jürgen Knez. The screwless, user-friendly connections on troughs, hoppers and covers are also useful. Knez explains: “We have created special closures in this case. The screws only have to be loosened slightly and then moved to one side using a lug or bracket. Everything remains in situ on the feeder, meaning the operator no longer has to hold loose components in their hands, and is able to remove the trough very easily.”

Downspouts: visual checks save time

Highly see-through, dustproof downspouts made of food-grade PETG are installed on all standard and B-Type feeders. This hard plastic is characterized by its transparency and shatterproof consistency. And it enables the operator to undertake quick visual checks deep inside the screw tube.

Rapid seal replacement

Replacing seals has also been made considerably easier by having a trough that can be removed from the front. “It only takes roughly five minutes to install a new seal on each feeder,” Jürgen Knez relates. Depending on what the customer requires, the sealing unit on the gearing mechanism can be kitted out with a wide range of different seals, for example for ATEX, food and pharma applications. Another safety bonus of the 2.0 version: seal replacement indicators have been included in the bottom and top sections of the gearing block, on the shaft guides, to alert operators in good time when seals need to be replaced and therefore prevent gearing and motor damage.

Servo motor as standard

Following the relaunch, the servo motor is our new standard from now on. It will be included in all versions of the new modular equipment generation 2.0. Benefit: compared to normal frequency-controlled motors, servo motors have a wide range of applications, given their extensive speed conversion ratio. Changing screws and screw tubes can often be dispensed with. At the same time, installation effort and equipment downtimes are reduced. At lower speeds, servo motors can effectively start at nominal torque. They can also utilize their full potential when high torque is required and therefore function with a great deal of precision. From this new generation onwards, feeders featuring AC motors will only have Efficiency Class IE3 motors installed.

Another bonus: delivery lead times are also reduced, because modular components are always in stock. At the same time, flexibility is increased, if modifications to feeders have to be undertaken at short notice.

Modular, Customized and Flexible

“In feeding terms, the drive mechanisms and the new load cells in the new equipment generation 2.0 enable us to bridge the previous gap between the ‘smaller’ DDSR20 2.0 and the ‘larger’ DDSR40 2.0 more easily,” Jürgen Knez explains. “This reengineering process has enabled us to start providing customized, purpose-specific feeders that are even more efficient than before.” The DDSR60 2.0 and the DSR103 2.0 featuring the new equipment generation 2.0’s new modular concept will be available shortly.

Contact us for advice!

Why not contact our Sales experts to arrange a personal consultation.